When I tell people that I got a soldering iron as a Christmas gift they usually give me the “I’m sorry for you” look. And when I tell them it was exactly what I wanted they tend to tilt their head to the side and squint there eyes a little in that “I’m slightly confused” look. I think I have yet to convince anyone that this is a great present and that they should want one too, but I’ll keep trying.

A soldering iron, you see, fits in with a list of other items you, in my opinion, really should have and know how to use: sewing machine, dremel roto tool, router (wood kind, not network kind though you should have one of those too), welding equipment, multimeter, and various and sundry hand tools. These are the kinds of things that you need to fix things. To build things. To invent things. These are the kinds of things most people have no use for. They think “why would I build it when I can buy it in a shiny case for half the price/the same price/twice as much?”. It isn’t really about the money, its about the instant gratification coupled with the idea that “they” (large companies) can do it all better than “we” (normal, dumb people) can. It seems either people get it or they don’t so I won’t push the issue too hard, but here is why I wanted a soldering iron.

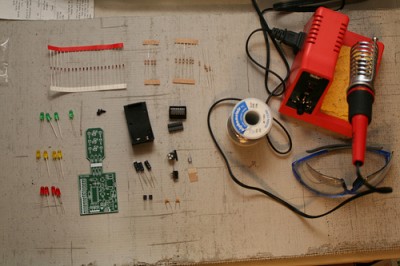

A soldering iron is the most critical tool when working with electronics. I wanted to be able to open them up, fix them, break them, assemble and dissamble them. I wanted to build things that don’t exist commercially and make the things that do exist commercially “better”. Before a few weeks ago I’d never soldered before. Heck I don’t think I’d even seen anyone solder. So I got on the internet. I watched this great video from Make and then read some how-tos online and got to work. In addition to the iron I’ve picked up: lead-based solder, lead-free solder, desoldering wick, and a desoldering pump. My first project was a stop-light kit (instructions here). I picked it for two reasons. One, I saw it and thought this would go great with Wesley’s train table and two, it was the cheapest kit they had on the racks. An added benefit is that it had a high number of pieces to solder and this being practice, more is better.

Please note the ton of little parts and of course the safety glasses (which I always wear, mom!). After soldering on the first resistor I had a minor epiphany. This isn’t that hard. It’s harder than they make it look on the video, but not as bad as I thought. The solder doesn’t stick to the green parts of the circuit board only to the metal. So my fear of everything running together wasn’t so bad after all. But after two minutes of being happy I realized I had made a big mistake. I had purchased lead-based solder. This is the traditional type, but recently laws have changed (for commercially produced products) and new lead-free solder has been introduced. The benefits of lead-free solder are that it is lead-free. The drawbacks are that it melts at a higher temp (which means you have to heat components longer and hotter which can damage them) and that it is prone to tin whiskers (which should be the name of a punk band). This project, as I mentioned was for Wesley. So being a good parent I realized that I needed to de-solder this and redo it with lead-free solder. This is what happens when you pick out your solder first and your project second.

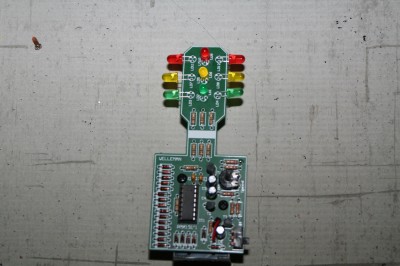

And then I screwed it up. Somehow when desoldering the first component I took the copper off the board. It got caught I think on the a bit of solder on the post of the resistor and peeled up. Maybe it’s a cheap PCB, maybe it’s my total and complete lack of experience or maybe I just need a small vise to hold everything so I have enough hands to do it properly. Whatever the case, I knew I had killed it. But did that stop me? No, I kept right on soldering each and every piece in place. I figured it was for practice anyway and knowing it wasn’t going to work took the pressure off. And then when I put in the battery, do you know what happened? Nothing. Even though it was the outcome I expected I’ll admit to being a little disappointed. It looks cool though.

On a more practical note: I have an mp3 player. That mp3 player had a little problem. Namely it didn’t play mp3s any more. I found this out while driving down with Dave in the moving truck to Austin. I’d plan to play the roughly 15gb of music on the trip. I wish I had checked ahead of time as I got really tired of the 25 songs I had on my other little mp3 player. After we moved down here I just put it in a box and periodically thought longingly of the days past when I could play my music away from home. And finally a few months ago I disassembled it to see what was the matter. From the behavior I figured it was the battery. A quick look inside didn’t show any blown components or burnt circuitry so I figured a failed battery was a likely candidate. Last week I found one online and ordered for $15 including shipping. A bit of quick soldering (and one burn through my fingernail) and I have a working mp3 player again. If I’d replaced it with a new one I’d have shelled out a couple of hundred dollars.

I’ll probably pick up another one of these kits and try again. I’d still like to see the lights blink (the timing is adjustable and everything). The one I have now will become desoldering practice and some of the components will probably get used for other projects. For now I need to learn a bit more about electronic circuits (pretty much all of my college physics has melted away by now). Once really I get the hang of this I can build an arduino and have some real fun.

I have an electronic testing lab that is in need of being assemled, it’s yours if you want it.

Soldering irons were to my dad like handsaws are to regular non-geek people. Now you need an oscilloscope and a cool magnifying light on an articulated stand. Then the world is yours!

Thank you for wearing the goggles.

Burned though your finger nail? You could shoot your eye out!!!

I get it…I actually want one too; but clearly not for the same reasons. You and Amber can have fun doing craft items too. I’ve always wanted to do stained glass windows since I saw them done on a craft show once. They were actually ornaments. And you solder them togeter with either lead or copper.

Although I clearly see it now…next year Wes and Jillian will both have metal halloween costumes

I wanted to do stained-glass a long time ago. My stepdad did it for a while. Never got to though. You can also use a soldering iron to cut nylon fabric without it shredding and threads coming lose. Useful for things like sewing together kites and tents and other outdoor gear. You are probably right about the costumes. Even if they are forest creatures of some kind they’ll probably get blinking LEDs or something.